Engineered for heavy machinery and renewable energy systems, QD Magnet’s ferrite magnets combine affordability with unmatched durability. Featuring zinc/aluminum anti-corrosion coatings and compressive strength ≥150MPa, our products outperform in wind turbines, conveyor systems, and hydraulic equipment. Leverage our bulk pricing model (MOQ 500 units) and JIT delivery to minimize inventory costs. With 98% on-time shipment rates, we empower industries to achieve sustainable, high-volume production.

As electric vehicle production surges, QD Magnet delivers automotive-grade ferrite magnets meeting IATF 16949 standards. Our corrosion-resistant zinc-coated magnets excel in EV traction motors, battery sensors, and charging systems, offering:

• High coercivity (HcJ ≥320kA/m) for vibration resistance

• Thermal stability across -40°C to +180°C operating ranges

• Custom multipole magnetization for compact motor designs

With 80% of components produced in-house, we ensure supply chain transparency and 45-day lead times for Tier 1 suppliers. Leverage our material test reports (MTRs) and PPAP documentation to accelerate your qualification process.

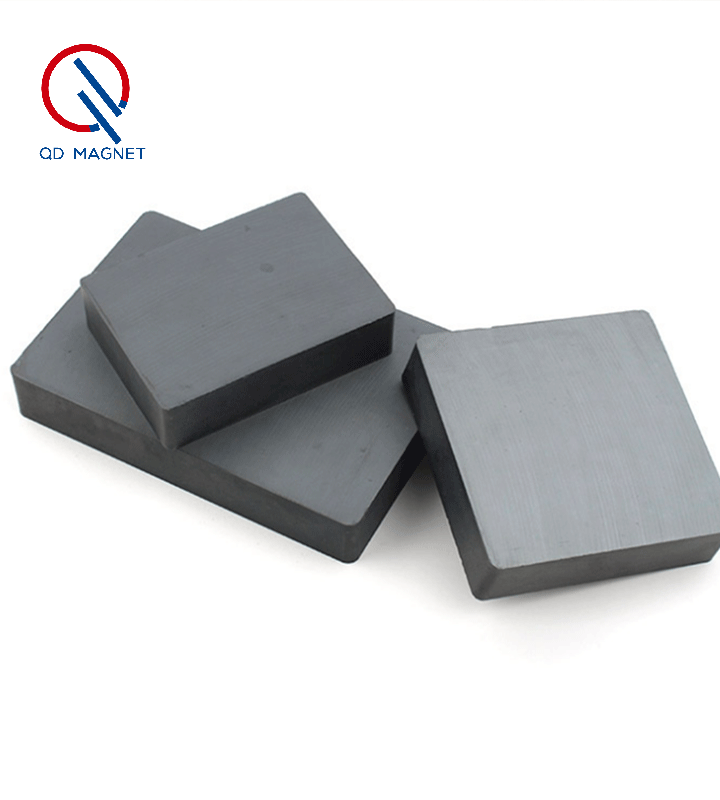

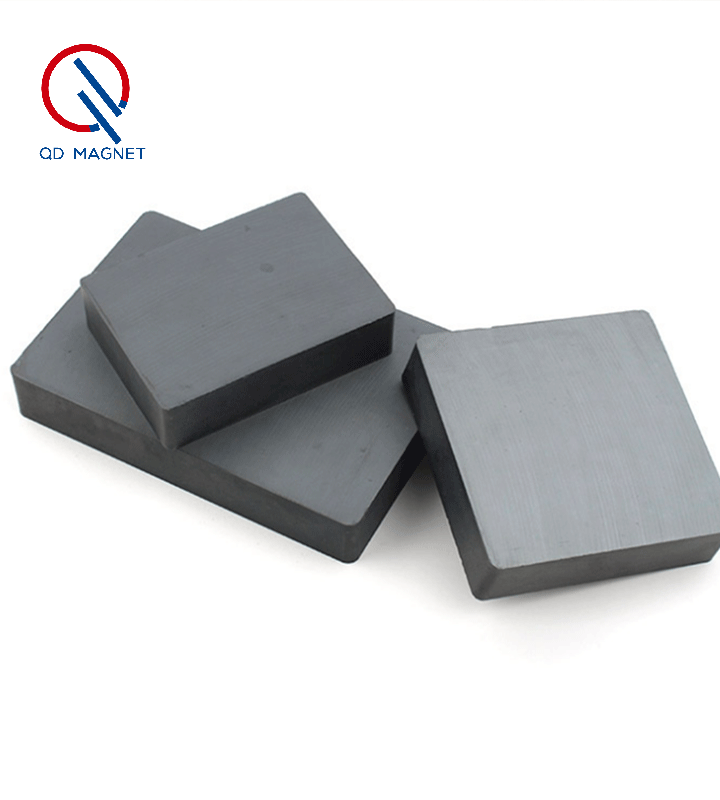

QD Magnet’s ferrite magnets revolutionize industrial motor performance through optimized magnetic flux density (Br 400-420mT) and low eddy current losses. Designed for servo motors, HVAC systems, and automated machinery, our magnets reduce energy consumption by 15-20% compared to standard alternatives.

With proprietary sintering techniques and ISO 9001-certified quality control, we guarantee ±1% dimensional tolerance across mass production batches. Customizable in arcs, blocks, or segmented shapes, QD Magnet solutions withstand temperatures up to 250°C while maintaining BHmax stability.

Partner with our engineering team for magnetic circuit simulations and rapid prototyping – achieve IEC 60404-8 compliance without compromising cost-efficiency.

QD Magnet’s ferrite magnets deliver unmatched stability in motor applications. Engineered for high coercivity and temperature resistance (up to 250°C), our magnets reduce energy loss in automotive starters, pumps, and HVAC systems. With ISO 9001-certified manufacturing, we ensure ±1% tolerance consistency across batches. Customize dimensions, magnetization patterns, and epoxy coatings to match your design requirements. Partner with QD Magnet for magnets that outperform industry lifespan benchmarks.

QD Magnet supplies biocompatible ferrite magnets for MRI equipment, surgical robots, and drug delivery systems. Compliant with ISO 13485 medical device standards, our magnets offer:

• Non-toxic epoxy coatings validated for skin contact

• Ultra-low magnetic decay (<0.5% over 10 years)

• Micro-tolerance grinding (±0.05mm) for miniature assemblies

With Class 1000 cleanroom production and 100% eddy current testing, we meet critical healthcare industry requirements. Download our medical-grade material certifications or request sterile-packaged samples today.

Shenzhen QD Magnet Co., Ltd. is specializes in production of high-quality NdFeB magnets and various magnets assembly,For example, magsafe magnet ring, mounting magnets, hook magnet and magnetic thumbtacks, etc.We're providing one-stop service of slicing, punching, special machining, CNC, electroplating, magnetic design & assembly.

All products passed RoHS, Reach certification

We take pride in our reputation as a leading provider of top-quality magnetic products for businesses of all sizes.

Our commitment to excellence and customer satisfaction is unparalleled, and we strive to exceed our clients' expectations with every order.

Whether you're looking for custom magnets for a trade show or promotional magnets for a product launch, we have the expertise and resources to meet your needs.

Trust Shenzhen QD Magnet Co., Ltd. for all your magnetic solutions.

Offering one-stop services from slicing to magnetic design and assembly.

All products meet RoHS and REACH certification standards.

Specialized in custom magnet solutions for various business needs.

Renowned for delivering top-quality magnetic products with exceptional customer satisfaction.

Our magnets comply with ISO 9001, RoHS, and REACH standards, with material test reports available.

Yes, we specialize in custom geometries using CNC grinding and diamond cutting tools.

Yes, ferrite magnets can be customized to meet specific requirements. QD MAGNET offers custom sizes and shapes to fit various applications, ensuring that you get the right magnetic solution for your needs.

MOQ starts at 500 units for standard items, flexible for long-term partnerships.

Automated pressing and sintering processes with hourly QC checks on density and dimensions.

Copyright © - Privacy policy