Withstand extreme conditions using QD Magnet’s Magsafe magnets rated for -40°C to +120°C. Ideal for outdoor electronics, EV charging ports, and industrial IoT sensors. Our epoxy-free bonding technology ensures zero VOC emissions, meeting REACH and Prop 65 standards. Customize shielding layers (Mu-metal/ferrite) for EMI-sensitive applications.

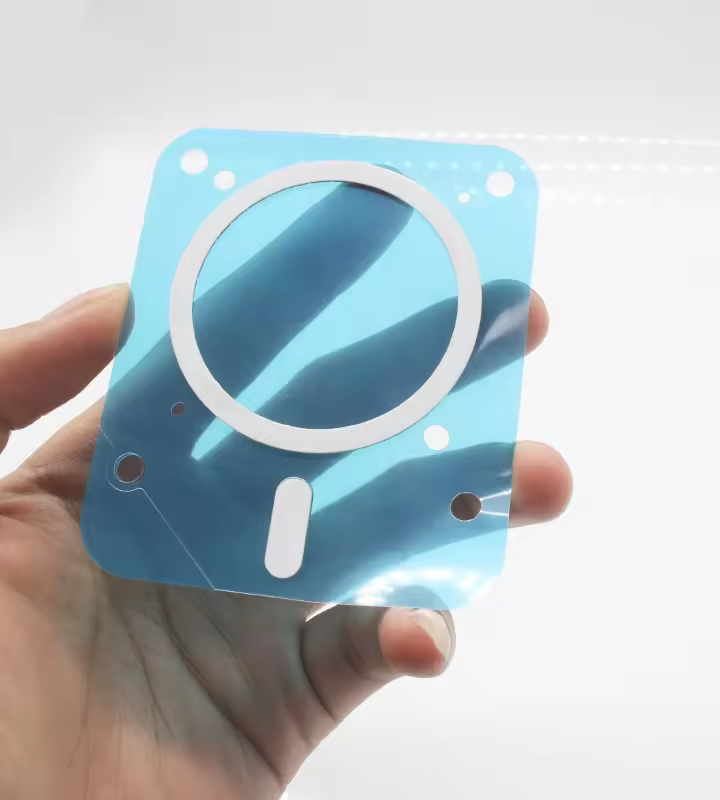

Minimize device thickness with QD Magnet’s 0.8mm flexible Magsafe sheets. Ideal for smartwatches and AR glasses:

Bend Radius: 3mm without flux loss

Multi-Layer Shielding: 30dB EMI reduction

Adhesive Options: 3M™ 300LSE or custom PSA

Request sample kits with 10+ thickness/field strength combinations.

Ensure sterile, tool-free connections in MRI-compatible equipment with QD Magnet’s medical-grade Magsafe assemblies. Features:

Biocompatible Encapsulation: USP Class VI-certified silicone

Zero Interference: <0.01T stray field at 10cm distance

Autoclavable: Withstand 134°C steam sterilization cycles

Download ISO 13485-compliant material certifications for FDA submissions.

QD Magnet’s high-cycle Magsafe solutions enable sub-second robotic tool swaps with 20N holding force. Technical highlights:

Fail-Safe Design: Permanent magnet + electromagnet hybrid system

Position Feedback: Integrated Hall effect sensors (±1mm accuracy)

Dust Resistance: IP69K-rated stainless steel housings

Access CAD files for direct integration into KUKA/FANUC-compatible systems.

QD Magnet’s automated production line delivers 500K+ Magsafe units/month with 99.95% consistency. Capabilities include:

In-House Magnetization: Axial/radial fields up to 4000 Gauss

100% AOI Inspection: Detect micro-cracks (10μm) and flux deviations

Sustainable Packaging: Recyclable trays and anti-static films

Explore our volume discounts for orders exceeding 50K units.

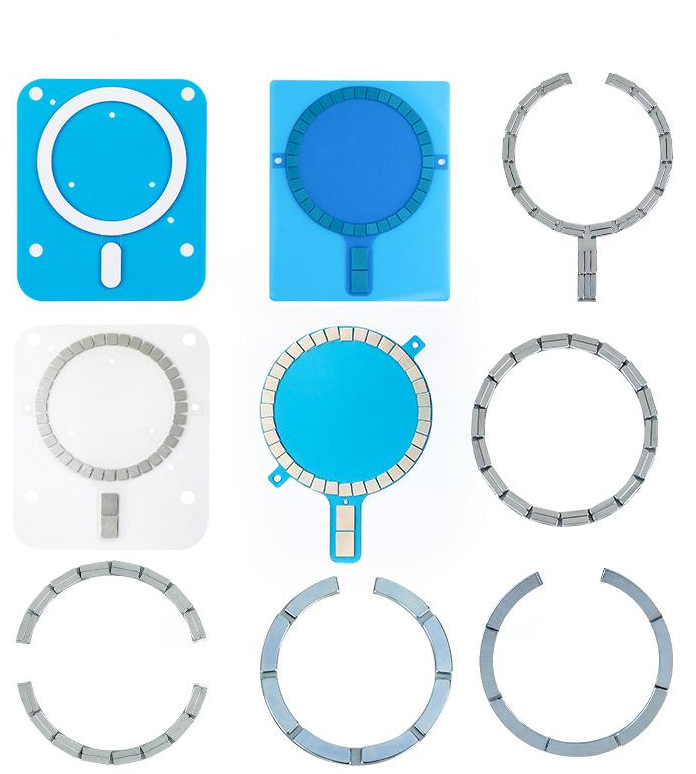

Shenzhen QD Magnet Co., Ltd. is specializes in production of high-quality NdFeB magnets and various magnets assembly,For example, magsafe magnet ring, mounting magnets, hook magnet and magnetic thumbtacks, etc.We're providing one-stop service of slicing, punching, special machining, CNC, electroplating, magnetic design & assembly.

All products passed RoHS, Reach certification

We take pride in our reputation as a leading provider of top-quality magnetic products for businesses of all sizes.

Our commitment to excellence and customer satisfaction is unparalleled, and we strive to exceed our clients' expectations with every order.

Whether you're looking for custom magnets for a trade show or promotional magnets for a product launch, we have the expertise and resources to meet your needs.

Trust Shenzhen QD Magnet Co., Ltd. for all your magnetic solutions.

Offering one-stop services from slicing to magnetic design and assembly.

All products meet RoHS and REACH certification standards.

Specialized in custom magnet solutions for various business needs.

Renowned for delivering top-quality magnetic products with exceptional customer satisfaction.

Magsafe magnets are commonly used in phone cases, wireless charging systems, and other electronic devices. They provide strong magnetic connections that enhance the usability and functionality of these products, ensuring secure attachment and efficient performance.

Magsafe magnets offer specific design features optimized for ease of use with magnetic connections. They typically provide strong, reliable performance in applications like wireless charging and magnetic mounting, ensuring convenience and effectiveness compared to other magnet types.

Yes, QD MAGNET offers customization for Magsafe magnets to meet specific requirements. We can tailor the size, strength, and design of the magnets to fit your unique applications, ensuring they deliver the desired performance and functionality.

Industries such as electronics, telecommunications, and consumer goods benefit from using Magsafe magnets. They are particularly useful in products requiring strong, reliable magnetic connections, such as smartphones, chargers, and various electronic accessories.

To maintain their effectiveness, Magsafe magnets should be stored in a cool, dry environment away from direct sunlight and extreme temperatures. Avoid exposing them to strong magnetic fields or physical stress that could impact their performance.

Copyright © - Privacy policy